Contact

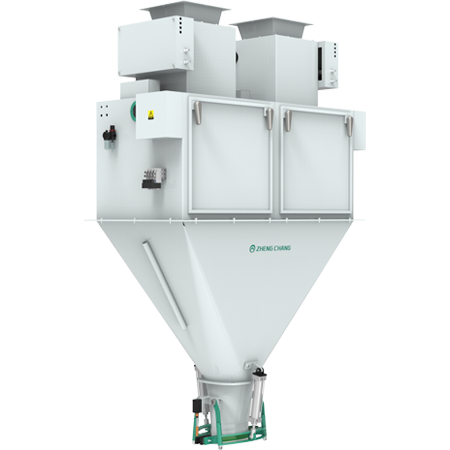

Flow control and rated packing in industries like grain, feed, silos, cement, chemical, building materials, etc;

With packaging and weighing specialized instruments as the core, combined with programmable controller logic, high-

precision weight sensor detection weight signals are output to complete bag clamping and fast/slow filling;

Self detecting over impulse and other functions to achieve weight packaging of different specifications;

Intelligent weighing instruments can display both gross weight and net weight simultaneously;

Automatic tare weight removal and zero position tracking, automatic detection and correction of weighing errors;

Cumulative package count display function, the entire system is with dust suction vents to improve the environment;

Datas can be collected into the computer and ERP, automatically calculating the weight, package number, errors, etc.

Model | Application (feed) | Packing speed (bag/min) | Packing accuracy | Packing volumn(kg/bag) | Feeder type |

|---|---|---|---|---|---|

SDBY-II(S) double-hopper | Pellet | 10~12 | ±0.2% | 20~50 | self weight |

SDBY-P(S) double-hopper | Pellet Flake-shape Concentrate | 10~14 | belt | ||

SDBY-F(S) double-hopper | Concentrate Premix | 10~12 | auger | ||

SDBY-F(I) no-hopper | Concentrate Premix | 3~5 | auger |