Contact

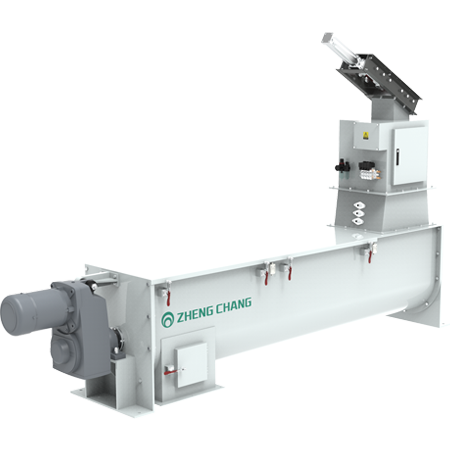

SYPY500 oil and fat post-coater

The feed gate of the flow scale can adjust the feed flow rate, ensuring stable feed inlet and accurate measurement;

The system adopts high-precision weighing sensors, the unique flow arc-shaped plate can evenly flow the feed;

The arc-shaped plate uses mirror stainless steel to avoid the accumulation, maintain the zero point stability of the weighing plate, ensure the measurement accuracy of solid feed;

In the middle of the coating room, there is a curtain shaped feed flow, the fat is coated on both sides;

High-pressure atomization nozzle ensures a good atomization, the fat is coated efficiently and evenly;

The conveyor utilizes the screw belt to mix while conveying, improving the coating uniformity and avoiding agglomeration caused by nozzle dripping;

Each pitch of the screw belt is with a gap adjustment scraper to reduce the residue of feed in the conveyor.

| Model | Power (kW) | Capacity (t/h) | Liquid addition ratio% | Liquid metering accuracy% | Uniformity % | Air pressure (MPa) | Conveying distance (mm) | Pellet feed metering accuracy |

|---|---|---|---|---|---|---|---|---|

| SYPY500 | 4 | 10~30 | 1~5 | 0.3 | ≥ 90 | 0.4~0.6 | 2000/2500/3000 | ±1% |

| SYPY500J | 0.75+4 | 10~30 | 1~6 | 0.3 | ≥ 90 | 0.4~0.6 | 2000/2500/3000 | ±0.3% |