Contact

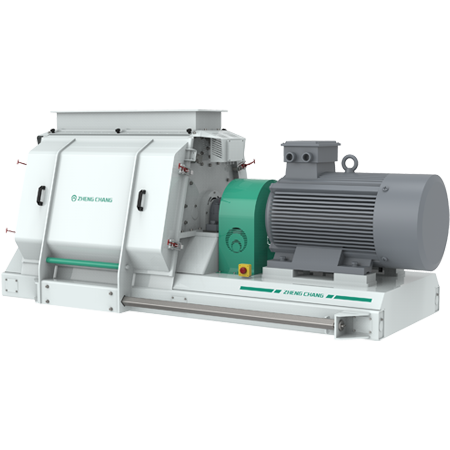

Optimized base structure increases the rigidity, reducing working vibration and improving stability;

Rotor assembly with related parts optimization further improve the dynamic balance accuracy;

8 sets hammer and 4 sets encrypted hammer scheme for different application scenarios to improve the fineness of grinding;

Optimization of the grinding chamber structure to further reduce the risk of insufficient feeding at the pressure screen frame;

Optimized design of the pressure screen frame structure enhances the convenience of operation and stable use;

Improved coupling selection, using a conical sleeve type serpentine spring coupling for faster and more convenient disassembly;

For the crushing of special feed materials, optional air system equipped to further disrupt the feed circulation and improve efficiency;

Grinding fineness is distributed between 30 to 60 mesh, suitable for processing of aqua feed and pet food raw material;

Application of high-quality sensors enables the operation to be controlled at any time, safer and more precise finished products.

| Model | Power(kW) | Φ2.0 sieve plate corn (t/h) (moisture≤13.5%) | Φ1.0 sieve plate corn (t/h) (moisture≤13.5%) |

|---|---|---|---|

| SFSP72×30 | 37/45 | ≥4.6/≥5 | ≥2/≥2.5 |

| SFSP72×38 | 45/55 | ≥5.6/≥6.5 | ≥2.5/≥3 |

| SFSP72×50 | 45/55 | ≥6.8/≥9 | ≥3/≥4 |

| SFSP72×60 | 75/90/110 | ≥9.5/≥11.5/≥13 | ≥4/≥4.8/≥6 |

| SFSP72×75 | 110/132/160 | ≥13.5/≥16/≥19 | ≥6/≥7/≥8 |

| SFSP72×100 | 132/160/200 | ≥16.5/≥20/≥25 | ≥7/≥9/≥12 |

| SFSP72×150 | 220/250 | ≥27/≥30 | ≥13/≥15 |