Contact

With the rapid development of information technology such as 5G and AI, it has also promoted the intelligent transformation and upgrading of feed factory production. By empowering the application of technologies such as remote monitoring, big data analysis, and digital twins in the field of feed engineering and equipment, it can greatly save labor costs, improve production efficiency, enhance equipment stability, and ensure product quality.

This time, the Zhengchang scientific research team has designed and developed a new generation of digital drying machines based on the characteristics of a wide variety of aquatic and pet grain puffed feed, diverse raw materials, and high quality requirements, to meet the intelligent and personalized management needs of customers in the production process.

The Zhengchang digital dryer control system is different from the traditional mode of matching the main equipment with the electronic control system. Through a large number of imported high-precision sensors and control execution units, it greatly improves the stability of equipment operation and ensures efficient and reliable production of the dryer.

The entire system is based on big data collection, data simulation training, and simulation. It adjusts the temperature of the temperature zone and the opening of each temperature zone air valve in real time, reducing equipment energy consumption by 10-12 percentage points. While ensuring that the materials meet the required humidity, it maximizes the reduction of electricity and steam consumption.

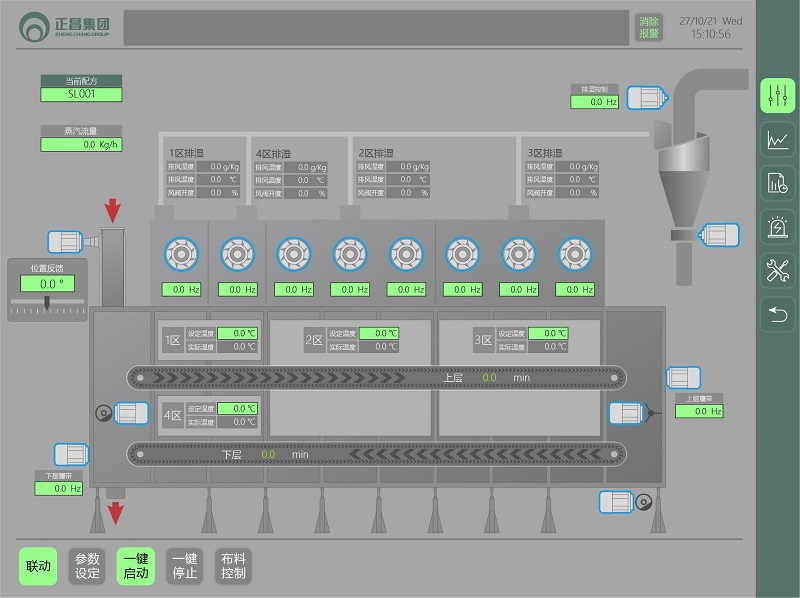

Automated production reduces manual labor

Drying machine control interface

The Zhengchang digital dryer meets the one click start stop function, which can automatically run and quickly heat up various temperature zones and enter steady state; The automatic fabric control system monitors the current fabric situation in real time and automatically adjusts the operating parameters of the fabric servo system to ensure fabric uniformity and reduce labor costs.

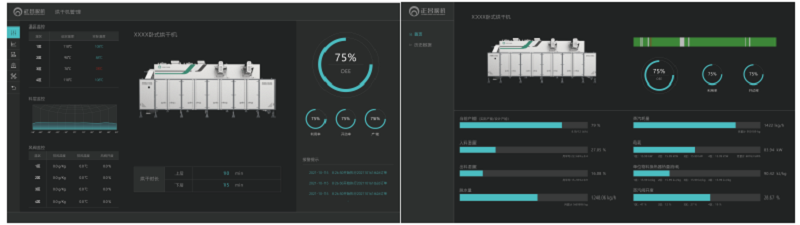

Digitized production to improve efficiency

Based on real-time monitoring and collection of actual production situation and key data of the dryer, fully utilizing physical models, sensor technology, operating history and other data, integrating multi parameter, multi formula, and multi probability simulation operation, providing control parameters for automatic operation under different material formulas, reducing equipment operation fluctuations caused by untimely feedback from the control system, achieving "quality and efficiency improvement" in the production of a single equipment, and avoiding energy waste caused by abnormal shutdown and equipment fluctuations in the control process.

"Fully transparent" production to ensure quality

The Zhengchang dryer control system can be optionally equipped with a digital monitoring system, which can view the equipment operation and historical production status in real-time on the workshop dashboard, PC administrator, and mobile phone. The production process is transparent, and equipment operation abnormalities can be traced back to single batch production orders, ensuring product quality.

Dryer monitoring interface

Real time monitoring of temperature and humidity, air valve opening, single layer drying time, and current material layer curve in each temperature zone to ensure uniform drying of materials in the same batch; Analyze core data, and view important information such as equipment utilization rate, equipment activation rate, and time utilization rate anytime and anywhere. Support report generation and export of key parameters, quantify production, optimize production parameters, and improve equipment efficiency.

After entering the market, the Zhengchang digital dryer has been widely used in the production of aquatic products and pet grains, and has been recognized by a large number of users for its high efficiency, stability, and simple operation. In the future, Zhengchang will actively respond to the national major strategy of "intelligent transformation and digital transformation", and combine with the development needs of customers, continuously innovate, build intelligent equipment and smart factories, and help the digital transformation of the feed industry.

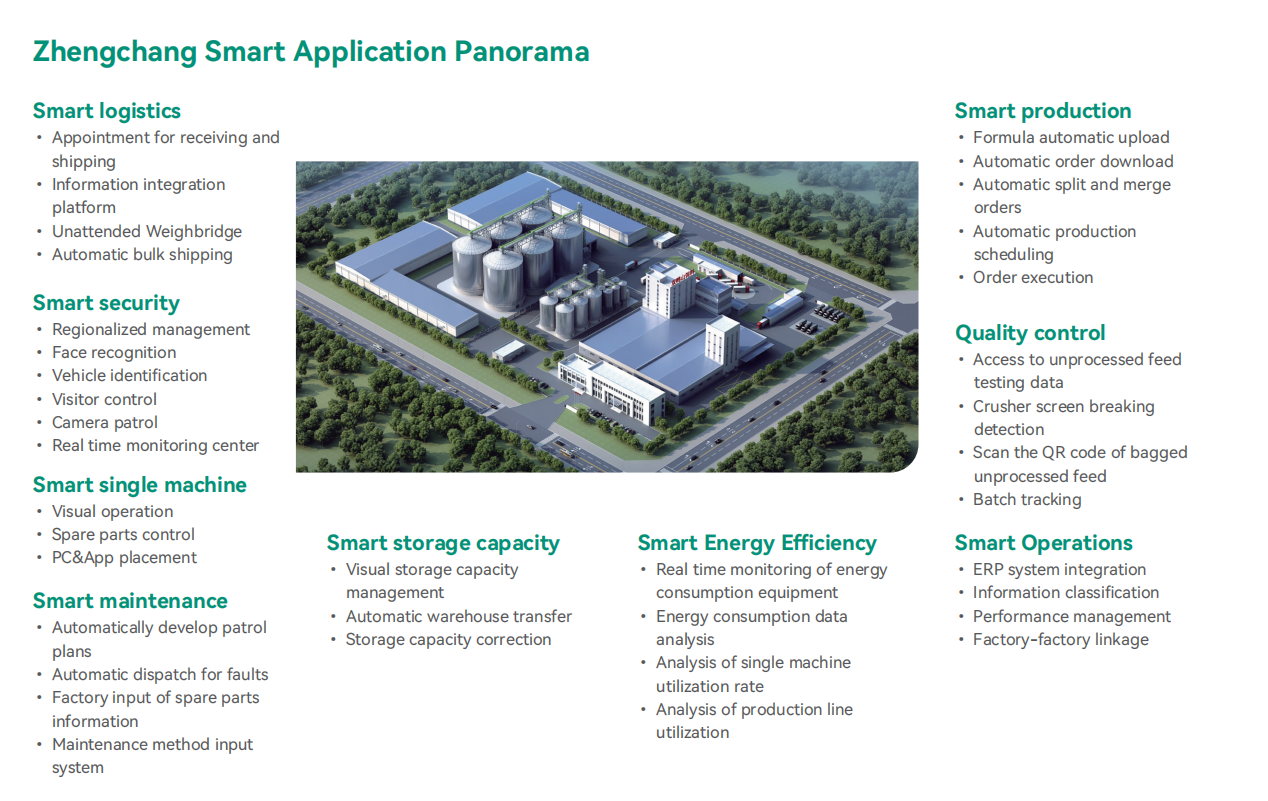

Zhengchang Intelligent Application Panorama