Contact

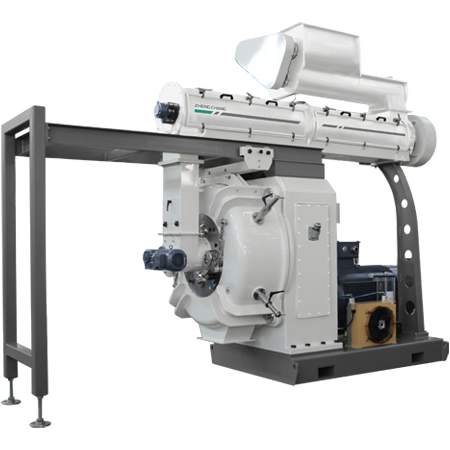

Stable, safe and reliable

The spindle adopts dual support structure to prevente shaking and giving greater ring die extrusion pressure;

The die roller adjustment device adopts an external structure, adjust the die roller gap without stopping the machine;

The roller adopts circulating water cooling, with low bearing temperature and long service life, reducing lubricant consumption;

The spindle and roller bearings with temperature measuring devices, monitor the working status of the bearings;

Key components such as the main shaft, transmission wheel, gears are all made of high-strength forged alloy steel;

The transmission system adopts imported brand bearings to ensure the service life of the machine;

Die and roller are made of high-strength forgings, with automatic gun drilling and vacuum quenching heat treatment;

Improved efficiency and high output

High gear transmission efficiency, high transmission torque, non slipping roller, increased capacity by 15%;

Forced feeding ensures uniform and smooth feeding;

Spiral feed plate design ensures uniform intake of sawdust from both side rollers, balanced squeeze force;

High automatic extent and strong applicability

On-site control cabinet, pellet mill automatic control system(Optional)interlocked with the central control room;

Intelligent system for operation report and accumulated operation time(Optional);

Intelligent system for oil temperature alarms, lubricant replacement reminders(Optional);

Universal design of the sawdust and straw pelleting,suitable for almost all biomass raw materials pelleting.

| Model | Power(kW) | Capacity(t/h) |

|---|---|---|

| MZLH858 | 250/280/355 | 3~4.5 |