Contact

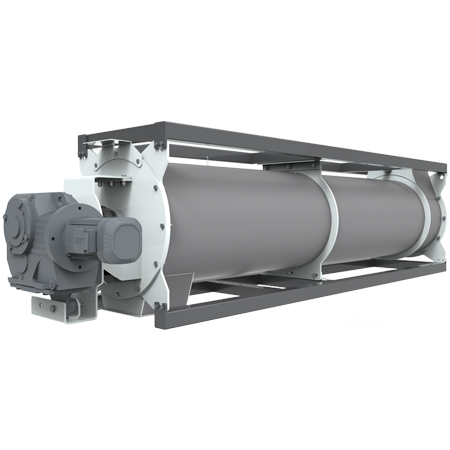

Outer layer of the cylinder with a thermal armor insulation layer, heated by electricity and temperature can be set;

Outer layer of the heat insulation with a foaming silicone rubber layer, reduce the heat loss of the cylinder and maintain a high gelatinization temperature of the feed (70-105 ℃);

Conditioner shaft with continuous spiral blades, uniform discharge mechanism. Low residue and no steam leakage;

Conditioner shaft is driven by a variable frequency reducer, the speed of the shaft can be adjusted according to the output and the required gelatinization time, achieving a long residence time of the feed in the cylinder;

Cylinder adopts a large door design, convenient for maintenance and cleaning.

| Model | Inner diameter of cylinder (mm) | Cylinder length (mm) | Power(kW) | Capacity (t/h) | Gelatinization (s) |

|---|---|---|---|---|---|

| STZG630b | 630 | 3700 | 5.5 | 4~18 | ≥85(15 tons) |

| STZG800a | 800 | 4000 | 5.5 | 8~30 | ≥100(20 tons) |

| STZG930a | 930 | 4000 | 5.5 | 10~35 | ≥125(25 tons) |

| STZG1200 | 1200 | 4500 | 7.5 | 20~45 | ≥128(35 tons) |