Contact

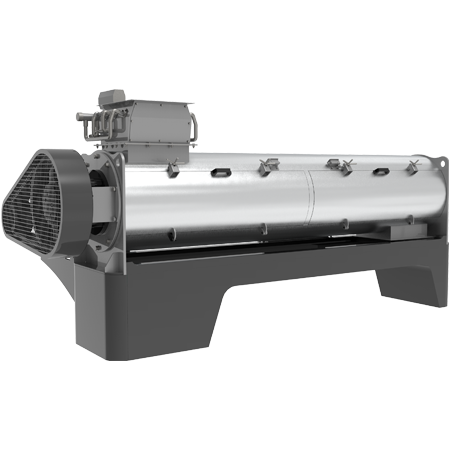

Used for mixing with a molasses addition ≥ 3%;

The motor drives the rotor to rotate through belt transmission;

Adopting compressed air atomization nozzle, the molasses atomization effect of is good;

Special angle paddle arrangement ensures the mixing time and uniformity;

The clearance between the paddle and the cylinder wall is ≤ 5mm, ensuring low residue;

Two large maintenance and cleaning doors facilitate cleaning, adjusting and replacing the paddles;

The full length direction cylinder insulation ensures the best mixing effect of molasses and material.

| Model | Cylinder diameter(mm) | Power(kW) | Capacity(t/h) | Mixing uniformity |

|---|---|---|---|---|

| STMH35A | 350 | 22/30 | 5~15 | <10% |

| STMH50A | 500 | 37/45 | 15~25 | <10% |

| STMH70A | 700 | 45/55 | 30~40 | <10% |

| STMH100 | 1000 | 55/75 | 45~60 | <10% |