Contact

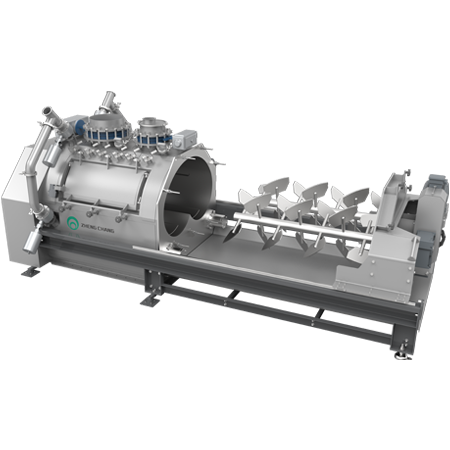

The rotor can be moved out as a whole through the slide rail, fast and effective cleaning with zero residue;

A stable and reliable sealing method ensures excellent vacuum sealing;

With 6 weighing sensors to accurately weigh incoming and outgoing materials, control the coating cycle in real time;

Oil and syrup coating, powder adding devices, precise control of proportions of additives, high coating uniformity;

Can configure CIP online cleaning system and hot air drying system to achieve automated cleaning function;

The whole machine is made of stainless steel and purchased from international top brands.

| Model | Capacity(t/h) | Liquid addition amount | Coating uniformity | Batch working time(min) | Power(kW) |

|---|---|---|---|---|---|

| CZPY500 | 1~3 | 6~35% | Cv≤7% | 4~6 | 7.5 |

| Model | Vacuum pump(kW) | Vacuum pump type | Residual rate | Breakage rate | Maximum vacuum degree(mbar) |

|---|---|---|---|---|---|

| CZPW500A | 7.5 | water ring pump | ≤0.5‰ | ≤0.3% | 40 |