Contact

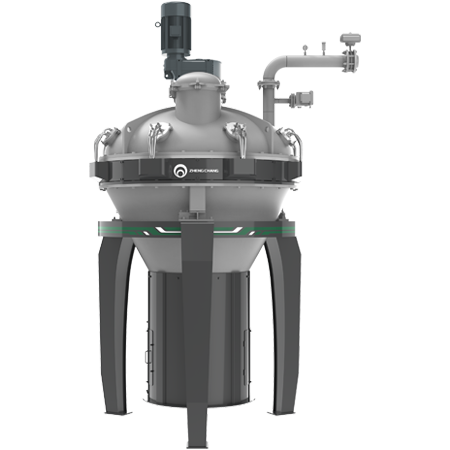

Uniform coating with low breakage rate can achieve the best quality;

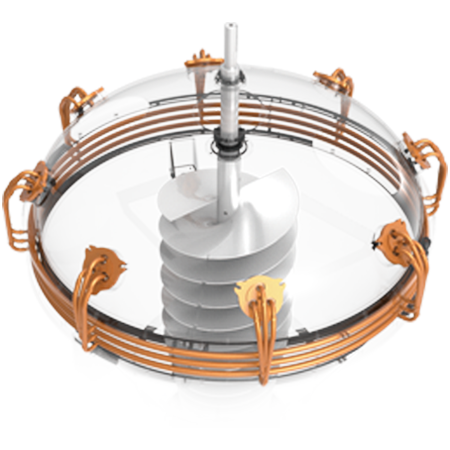

8-station circular fan-shaped nozzle system with no coating dead corners;

The new spiral rotor and feed gate structure greatly reduce pellet breakage and residue rate;

Accurate step-by-step vacuum release system ensures excellent liquid permeation effect;

The part in contact with pellets is made of stainless steel to ensure safety and hygiene;

The entire vacuum coater system adopts international first-class technologies, stable and reliable.

| Model | Volume(L) | Capacity (t/h) | Power(kW) | Liquid addition amount |

|---|---|---|---|---|

| SPZL2000 | 2000 | 4~8 | Main power 15kW, vacuum pump power 22kW | 1~36% |

| SPZL3000 | 3000 | 6~12 | Main power 22kW, vacuum pump power 22kW | 1~36% |

| SPZL4000 | 4000 | 12~15 | Main power 30kW, vacuum pump power22kW | 1~36% |

| SPZL5000 | 5000 | 15~20 | Main power 37kW, vacuum pump power 22kW | 3~36% |

Pellet diameter (mm) | Batch working time (min) | Coating uniformity | Residual rate | Maximum vacuum degree (mbar) | Vacuum retention |

|---|---|---|---|---|---|

| 1~30 | 5~7 | Cv≤7% | ≤0.5% | 40 | ≤100mbar / 6min |