Contact

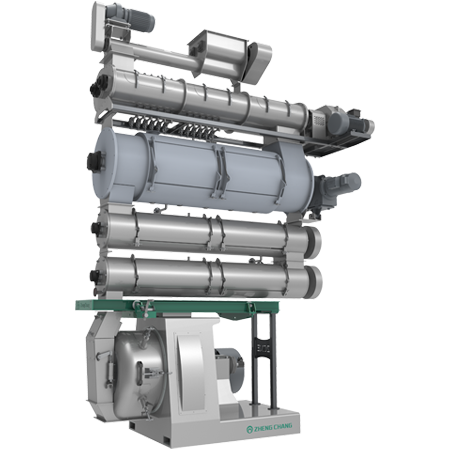

Advanced structure and stable operation

The gear transmission is made of high-strength alloy steel, and the gear surface is subjected to precision grinding and shaping treatment to ensure low noise, high transmission efficiency;

The transmission system adopts high-quality bearings with a long service life;

Optimize the reasonable configuration of the ring die line speed and roller size, more suitable for shrimp feed;

Automatic grease lubrication system and external thin oil circulation cooling system to ensure long-hour non-stop operation;

Electric ring die lifting device to facilitate the disassembly and assembly of the ring die and roller;

Excellent feed quality

Arch breaker feeding system ensures continuous and uniform feeding, the feeding cylinder with a steam outlet and lengthened design, effectively prevent steam leakage;

Conditioning system adopts combination configurations of DDC, retentioner, high-speed conditioner, ensure the gelatinization;

Long-lasting gelatinization retentioner improves the starch gelatinization, ensuring the appearance and water resistance of the pellets.

The retentioner cylinder adopts electric heating insulation, achieve preheating and precise temperature control;

High-speed conditioner to break up clumped feed, ensuring the uniformity and moisture of the feed, reducing defective feed;

Online moisture detection and feed quality optimization system(optional), automatically matching the amount of steam added.

| Model | Power(kW) | Capacity(t/h) |

|---|---|---|

| SZLH530 | 132/160 | 2.5~3.5 |

| SZLH600 | 160 | 3~4 |