Contact

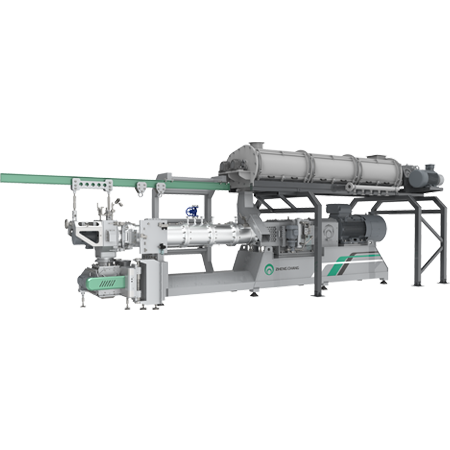

Used for precise processing of various formulas such as low starch, high protein, high fat;

Design concept of advance mold hole structure and hole layout, ensuring consistent pellet size with nice look;

The screw and bushing can be equipped with new wear-resistant and corrosion-resistant materials;

International first-class brand gearbox, torque limiters for reliable use and low maintenance costs;

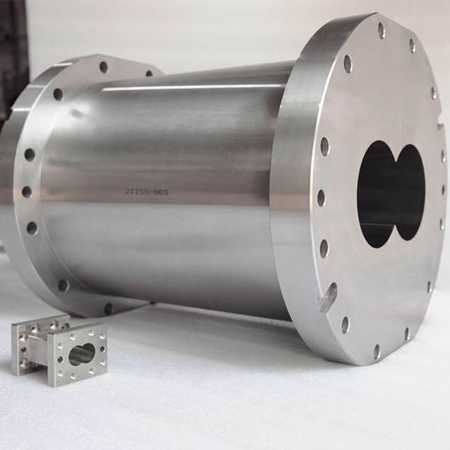

Overall forged bushing is formed in one piece, greatly reducing the risk of cracks, with a long service life;

Bushing wear detection technology, the wear of each segment of the bushing can be detected without dismantling;

Two density control systems can be configured to simultaneous processing of both floating and sinking feed;

Automatic control system: formula management, one click startup, load control, precise water and steam addition, online adjustment of mechanical energy, production information recording.

| Model | Power(kW) | Capacity(t/h) | |

|---|---|---|---|

| Floating feed Φ4.0 | Sinking feed Φ4.0 | ||

| SPHS100×2 | 110/132 | 2~3 | 1.5~2 |

| SPHS125×2 | 200/250 | 5.5~7.5 | 4~5 |

| SPHS155×2 | 315/355 | 10~12 | 6~8 |

| SPHS175×2 | 560/630 | 15~16 | 8~10 |