Contact

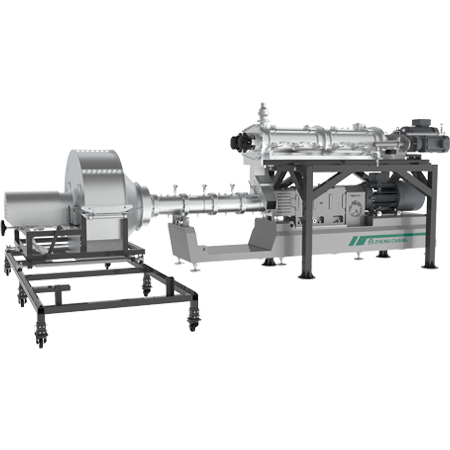

Small laboratory extruder achieve trial production of special and high-end formulas and precise processing in small batches, effectively reducing the waste of high-value raw materials during the experimental process;

Equal proportion to the large extruder in parameters and structure , ensuring the practicality of experimental data;

Single cycle channel heat exchanger cylinder, each section of the cylinder can independently heat or cool, meeting the needs of heating, gelatinization, and cooling for different materials inside the extrusion system;

Fully automatic steam control and water integrated pipeline system, based on capacity and set addition values, automatically adjusts steam thermal energy, STE and water addition, reducing human interference;

Enlarged cutting device, the shape of the high moisture pellets at the discharge port is effectively protected during the producing, reducing adhesion and deformation;

The high shear conditioning device, along with its unique rotor angle, blade arrangement, and variable steering design, achieves various conditioning effects (especially suitable for conditioning and mixing high moisture materials and dry powder raw materials);

The mechanical energy SME online adjustment automatically controls the input of mechanical energy, improving the adaptability of the extruding system to raw materials. Variable Venturi resistance valve (automatically adjusts valve opening according to SME set value).

| Model | Power(kW) | Capacity(t/h) | Length to diameter ratio |

|---|---|---|---|

| CPHS56×2 | 30 | 0.1~0.2 | 24:1 |

| CPHS75×2 | 75 | 0.8~1.5 | 20:1 |

| CPHS100×2 | 100/132 | 2~3 | 20:1 |

| CPHS125×2 | 200/250 | 5.5~7.5 | 20:1 |

| CPHS155×2 | 315/355 | 10~12 | 20:1 |