Contact

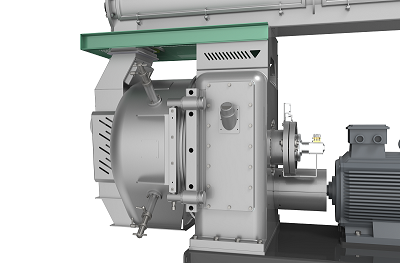

As the core equipment in the production process of pellet feed, the stability of the performance of the pelletizer and the maximization of output compared to similar models directly affect the production efficiency and economic benefits of the feed factory.

Improved overall efficiency, high production capacity, and lower overall operating costs

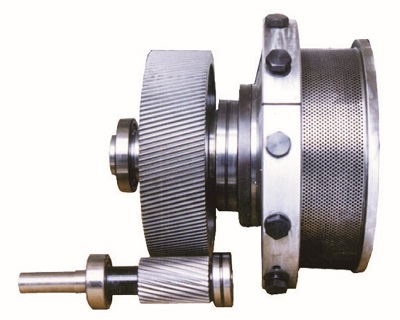

1. The fabric in the compression chamber is analyzed using EDEM discrete element method to ensure even distribution of materials between the two pressure rollers, ensuring uniform length of discharge from the ring mold, and high equipment production capacity;

2. Optimize the working width and speed parameters of the ring mold to improve the efficiency of the equipment;

3. The gear set is made of high-strength alloy steel with a large modulus design, strong load-bearing capacity, and long service life;

4. The gears are processed with precision grinding and tooth surface modification, resulting in low operating noise and higher transmission efficiency;

Stable, reliable, and secure performance

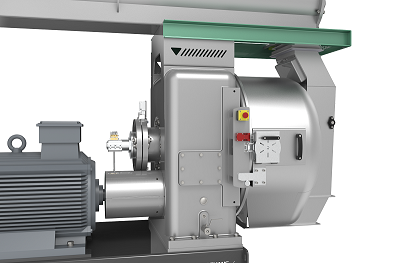

1. Using imported branded bearings to ensure the stability and long service life of the equipment;

2. The main transmission adopts a multiple combination sealing structure to ensure the sealing reliability of the transmission box;

3. An adjustable soft sealing structure is installed at the feed inlet to effectively prevent the leakage of steam and dust;

4. There is a mechanical opening protection mechanism at the door cover, equipped with emergency stop and safety switches to ensure safe operation;

Automated operation, convenient management and maintenance, and more user-friendly

1. Can configure the automatic control system of the granulator, making it easier to use;

2. The door cover adopts a new type of door shaft mechanism, which has strong supporting force and convenient adjustment;

3. Configure an automatic grease lubrication system to achieve timed and quantitative non-stop refueling;

4. Equipped with an electric mold roller disassembly and assembly system, the ring mold pressing roller disassembly and assembly is fast and convenient;

5. Optional oil circulation cooling and lubrication system can be equipped to make the equipment more suitable for continuous operation in high-temperature environments;